Antiadhesive and antimicrobial implants for visceral surgery prepared by cold atmospheric plasma and electrospinning

Postoperative adhesions are a significant health issue with major implications on quality of life and health care expenses. In particular, intra-abdominal adhesions arise after 50 to 100% of all abdominal operations, within the 12 months after any type of surgery. The severe consequences of these postoperative adhesions stand in stark contrast to the low level of awareness and knowledge among doctors and their cost is estimated in France between 60 and 600 million € per year. Adhesions may also be coupled to other side effects such as infections, which result in additional treatments and delay patient's recovery.

It is then necessary to design anti-adhesive and antimicrobial implants that will be active directly on the surgical site for an extended period. Polypropylene is widely used as implant in the visceral field thanks to its mechanical strength and its biostability, but its inert surface requires functionalisation to become active.

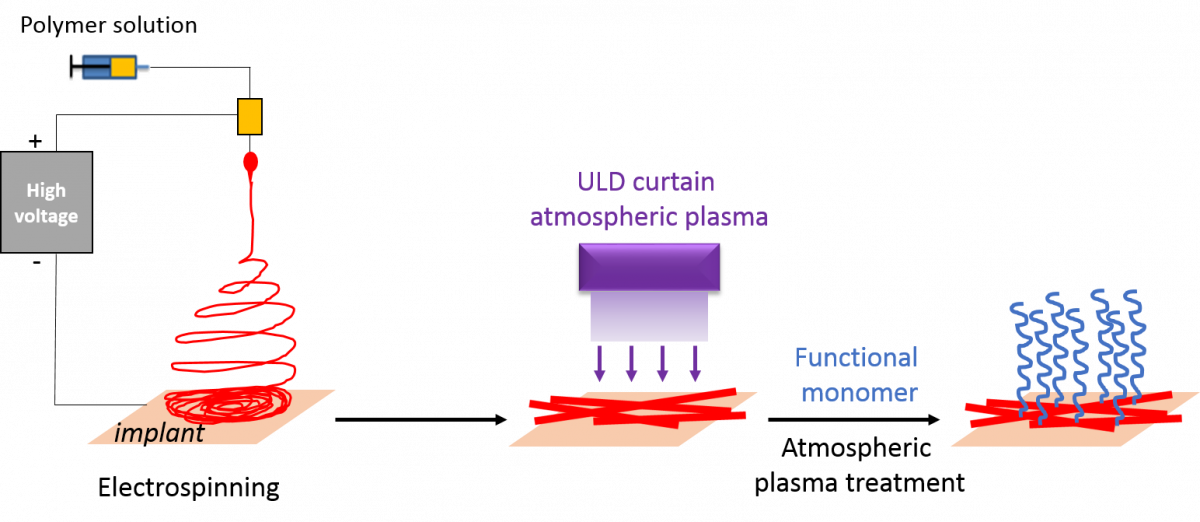

The aim of CAPSPIN project is thus to combine and optimise through experimental design two eco-friendly processes for the elaboration of antiadhesive and antimicrobial biodegradable nanofibres coated onto intraperitoneal polypropylene implants. Electrospinning process is an innovative process used to produce biodegradable monolithic and core-sheath nanofibres. Atmospheric cold plasma technology is used for the activation and functionalisation of different polymeric substrates at the extreme surface only. The chemical, physical and mechanical properties of all biomaterials designed will be fully studied through adequate characterization techniques according to the aimed visceral application. The keys to further industrialisation procedure, i.e. in vitro and in vivo stability of the coatings as well as biological activity of the implants will also be evaluated.